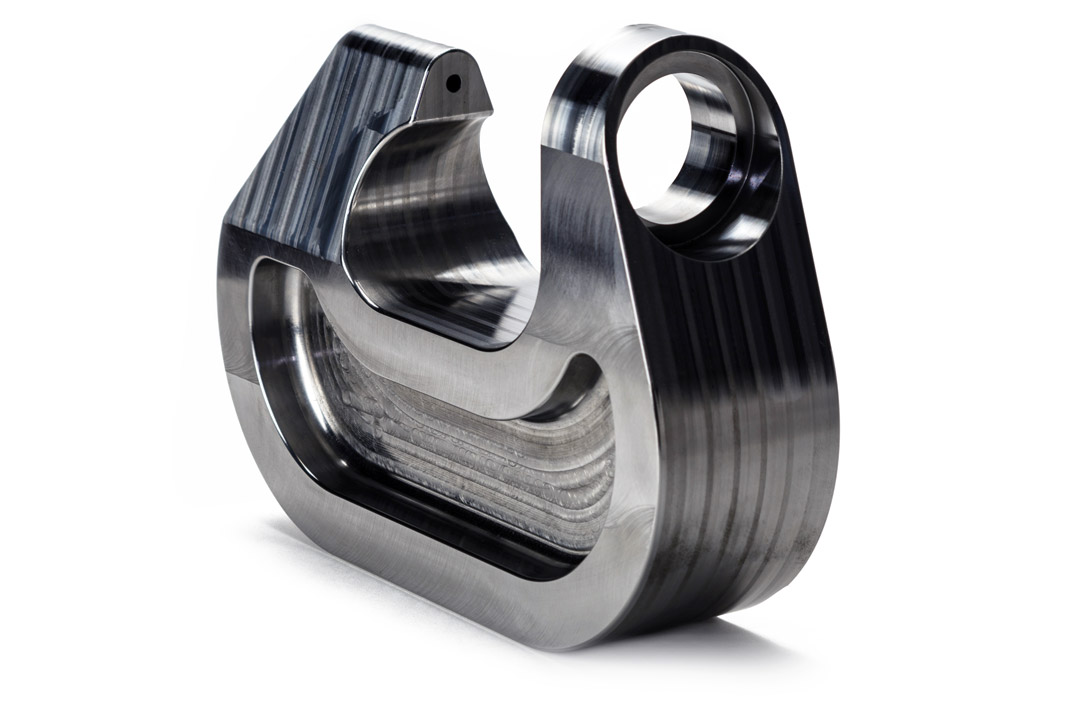

Machining:

Dylan’s machining capabilities range from simple 2-axis turned components to complex 5-axis milled details. We use state-of-the-art, palletized and robotic loaded, “cellular” machining centers with high-capacity, standardized, resident tooling and standardized work-holding. We use the premier programming software and maintain highly trained operators to assure that machined products delivered by Dylan Aerospace meets specifications and exceeds expectations.

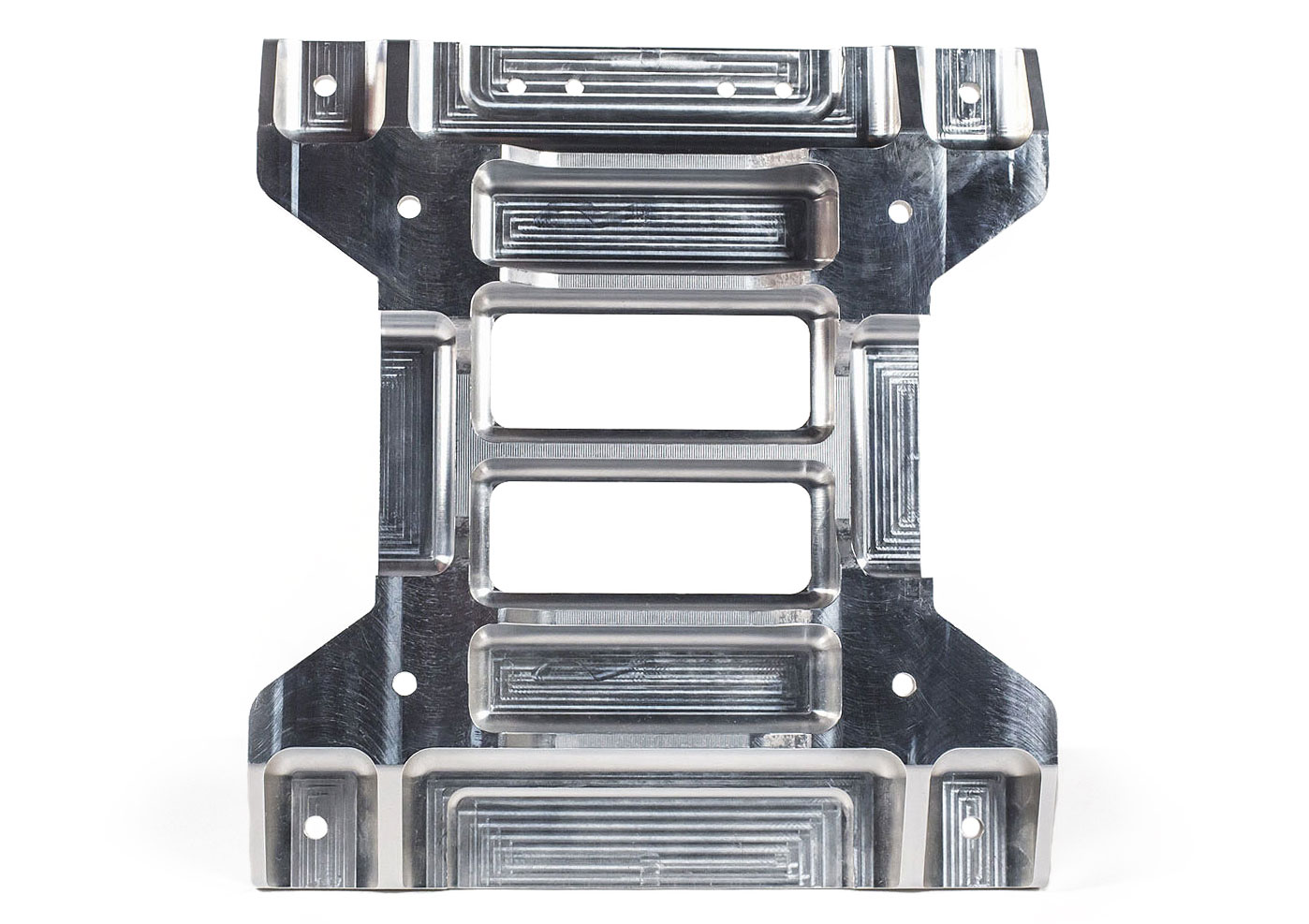

Fabrication:

Our processes include: CNC 5-axis milling, Sheet Metal brake forming, CNC high speed turret punching, tube forming, “T” tube pullouts, hydroforming and stamping of any number materials including aluminum, stainless, titanium and other alloys.

Finishing:

Dylan Aerospace delivers raw finished goods to complete “turnkey” finished and assembled products that meet or exceed standards in the commercial, business jet and military aircraft markets. Dylan has received quality approvals from major aircraft manufactures including Boeing.

Assembly:

We are an industry leader in the assembly of multiple-detail components into sub-assemblies and finished-assemblies. Dylan delivers this critical manufacturing step to a range of products in the commercial, business jet, and military aviation markets

Engineering:

Dylan Aerospace recognizes that a commitment to acquiring and maintaining the latest computer and machine technologies is critical to supporting our customers. We have committed to maintaining complete in-house CAD/CAM, CNC and CMM machine programming and reverse engineering capabilities, which allow us to offer complete manufacturing engineering and design for streamlining machining and tooling processes that result in manufacturing cost reductions.

Kitting & Distribution:

In support of our customers' Lean and Best Practice Initiatives, Dylan Aerospace offers kitting services to help streamline the flow of components to their assembly lines. Dylan has, or will make available for Prime customers, warehousing and detail storage facilities where finished goods may be stored and kitted to customer specifications, upon demand. These services provide just-in-time delivery to support and conform to our customers’ lean manufacturing processes.

Hydro forming:

With our high-pressure hydraulic press, coupled with precision tooling hydro forming by Dylan Aerospace is an economical source for rigid formed metal panels. Manufactured to tight tolerances with rigid materials our process of hydro forming produces parts with a superior smoother finish as well as significantly less thinning than traditional press forming.

Specialized Testing

Per our work statement we provide specialized mil-spec testing and evaluation processes. Some of our specialized testing services include Electrical Bonding Testing & Pressure Testing. The certifications we currently hold are listed on our CERTIFICATIONS page.

Supplier Management

Our Supplier Management & Procurement (SMP) Department has responsibility and authority to contract for MRO, capital, raw material, parts, processing, logistics, subcontract needs, shop and office suppliers, and services in a manner consistent with the needs of our organization. SMP’s responsibilities and authorities include determination of supply sources, commitments, negotiation of purchases, delivery, and return of goods. SMP is the channel through which normal requests regarding price, product, and delivery are made. Employees representing other functional areas may contact suppliers, or potential suppliers, for the purpose of acquiring technical, or other information, but have no authority to commit Dylan Aerospace contractually or financially.

SUPPLIER RELATIONS

It is the policy of Dylan Aerospace to treat all suppliers fairly, and impartially, while seeking to develop long-term relationships that mutually benefit all parties. In addition to competitive bidding, the supplier evaluation and selection process shall consider supplier ability, quality, delivery performance, capacity, financial status, location, integrity, and other factors as may be appropriate.

Suppliers are encouraged to share suggestions for product improvement and cost reduction opportunities, as well as updates on market and product information.

Supplier visits are customarily by appointment only.

For quotes, please contact estimating@dylanaerospace.com.

Thank you.